Acoustic Wall Panels

Acoustic Wall Panels

WhisperWall® is an upholstered acoustic wall panel system that is built directly into the wall and constructed on-site. An acoustic solution that doubles as an integral part of interior design.

In the decades since Materialised purchased the Australasian WhisperWall® license, the awareness of acoustics in interior design has increased enormously.

Sustainable Acoustic Absorber

The Martini dECO Quiet Board acoustic absorber is manufactured from thermally bonded polyester fibre with up to 80% recycled fibre content from post-consumer PET packaging. It has a Global GreenTag GreenRate™ Level A certification with a Global GreenTag Platinum HealthRATE™ certification and is therefore suitable for Green Star projects.

How It Works

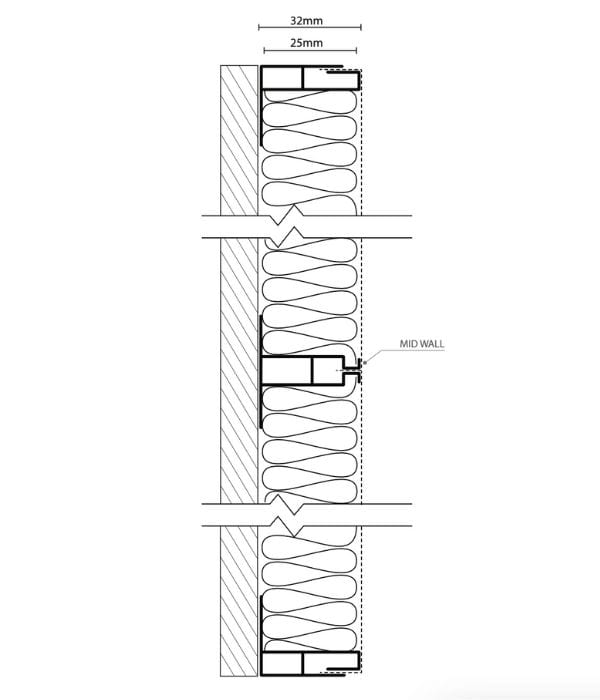

A patented polymer tracking system enables tightly stretching our commercial grade fabric over the acoustic absorbers for wall panel solutions. See NRC ratings in the table below.

With 58 tracking profiles to choose from we are able to cater for any wall design situation. The most common tracks are for 12mm, 25mm and 50mm acoustic absorbers. We can work with any specification nominated by an acoustic engineer.

NRC Explained

To quantify our product as a commercial acoustic solution, each is tested and awarded an NRC (Noise Reduction Coefficient) rating. The NRC relates to the absorption effectiveness of the material, and is calculated by averaging how absorptive a material is at four different frequencies.

Our Whisper acoustic products are tested at 125hz, 250hz, 500hz, 1,000hz, 2,000hz and 4,000hz. Taking the average number, it is then applied to the NRC scale of 0 to 1. A perfectly sound absorptive material achieves a 1, whereas a 0 indicates no absorption.

Made In Sydney

There are no standard or pre-fabricated panels as we assemble and install onsite with our team of experienced installers.

We print designs onto a flame retardant fabric with a modified weave, allowing air to freely pass through, whilst maintaining printed integrity. Choose designs from our vast print library or work with our team of in-house designers to supply your own.

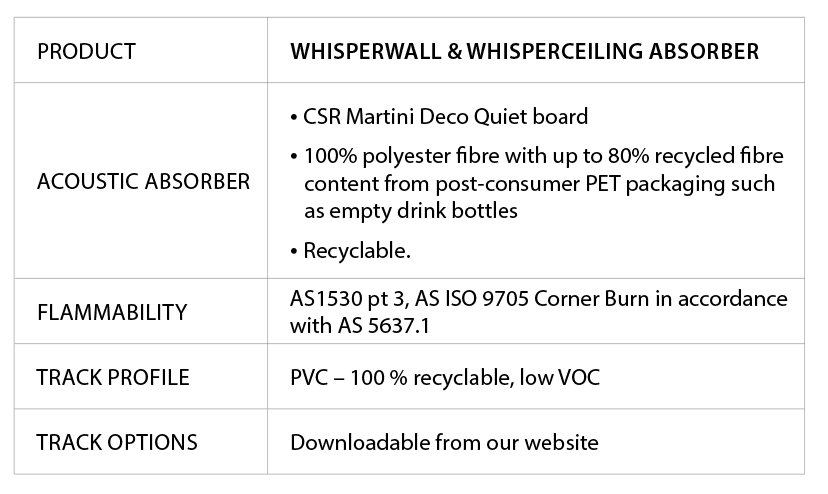

Acoustic Wall Panels Specs & Details

Technical Overview & Drawings

“The staff at Materialised took on a major part of the internal installation, which included the printed artwork and acoustic insulation. Their workmanship and attention to detail was, in a word, “extraordinary”. We could not be happier with the final outcome and I can’t thank Materialised enough.” Anthos Simon, General Manager, Edge Content & Technology (Boutique Event Cinema, George Street)

Whilst the name WhisperWall® suggests an acoustically quiet space, your clients will be yelling in praise of the outcome! Give us a shout, and we can show you the system.