Wyzenbeek vs Martindale Abrasion Testing

Is there a difference between Wyzenbeek and Martindale testing?

There are two standard tests for woven upholstery abrasion resistance, also known as the rub rate: Martindale and Wyzenbeek.

Both involve testing equipment which simulate the natural wear of a seat cover, culminating in a number of ‘rubs.’ The higher the number, the more resistant the material is to abrasion.

Unfortunately, there is no direct correlation between the two test methods.

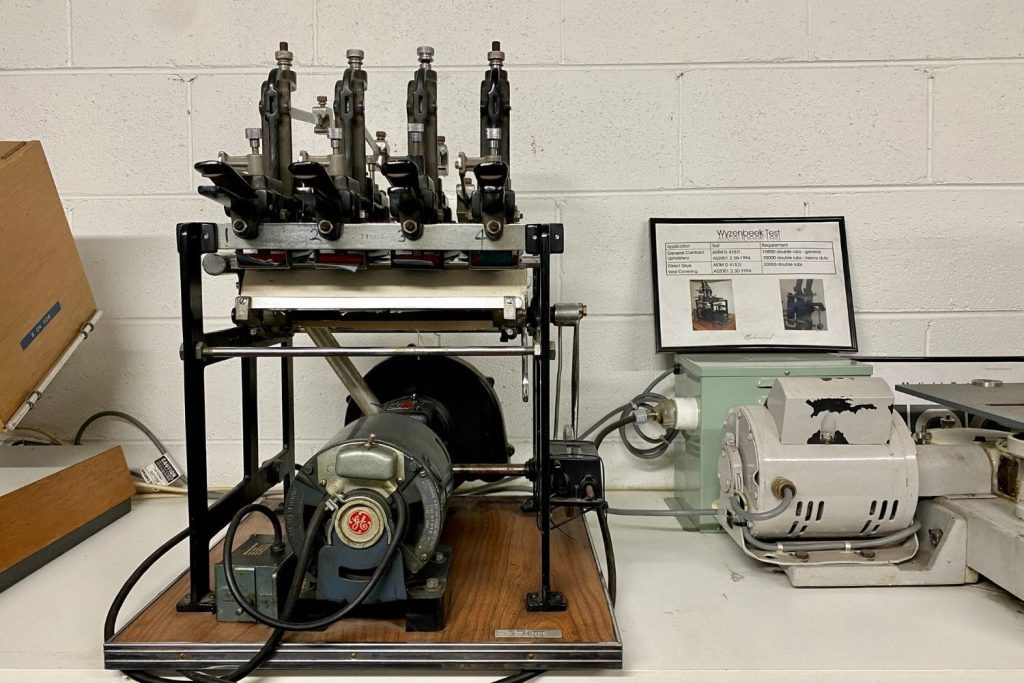

WYZENBEEK

Wyzenbeek is a machine named after its inventor, Andrew Wyzenbeek, where the fabric can be tested to give an indication on the suitability of a particular fabric. It is mostly used for upholstery fabric.

The test is universally recognised and only authorised testing bodies should provide certification. This method is widely used in the United States.

The fabric being tested is set up on the machine and abraded against an option of two materials: One being cotton duck and the other a wire mesh. We generally test on the cotton duck.

The fabric is abraded back and forth and each motion is 1 rub. The ‘end point’ is determined when the subject fabric sample shows two consecutive yarns to have broken. The test is stopped and the results are recorded at that point.

An accepted outcome for residential use is 15,000 double rubs and heavy duty commercial use, 30,000.

MARTINDALE

Martindale is another machine that can be used to test fabric for its upholstery suitability. It is named after inventor J.G Martindale who penned many books in the 1970’s such as ‘A Selective Bibliography Of Textile Engineering.’

The fabric being tested is set up on the machine and abraded against a wool fabric that is universally used. The motion of abrading is more like a “figure eight” and the number of oscillations is recorded.

When two consecutive yarns have broken the test is stopped and the results are recorded.

An accepted outcome for residential use is 20,000 cycles and heavy duty commercial use, 40,000.

TESTING AT MATERIALISED

We can test for both at Materialised but we tend to test our upholstery fabrics with the Wyzenbeek method as the motion in the test method is more akin to the abrasion that would take place when a person sits and stands on a seat.

As mentioned earlier, there is no direct comparison for each test as they are very different.

However, whatever test report you may be assessing, if the number is satisfactory you can be confident that the fabric specified will be fit for purpose.