It’s Materialised 1990 and this was the decade when, in the midst of the “recession we had to have” along with 20% interest rates, our illustrious leaders decided we should eliminate import tariffs and “have a level playing field.”

The only problem there is we were the only mugs playing on the ‘field’. The Australian textile production industry, along with the associated industries, started on a terminal downward spiral. Weaving mills, dyers and printers were closing by the month.

New rules were emerging regarding Flame Retardancy especially in hospitals, nursing homes and hotels.

Materialised 1990 And Flame Retardancy

Two options to meet this demand were either to topically treat conventional textiles with a Pyrovatic Acid or; adopt the new modified polyester technology, building the flame retardant into the polymer of the fibre, known as ‘inferential Flame Retardancy’.

We chose the latter!

This inherent flame retardant was durable for the life of the fabric, was non toxic and passed the most rigorous tests. Having made the decision to follow the polyester path, the next big quest was to find an effective way to decorate such fabrics.

We took the then adventurous step to adopt the relatively new technology of dye sublimation printing these polyester fabrics. Dye sublimation transfer involves printing designs and textures onto a release paper which, when heated and pressed to a particular temperature, effectively ‘dry dyes’ the design into the fabric. This was revolutionary in that it offered options of virtually any application; from filmy sheers to robust upholsteries.

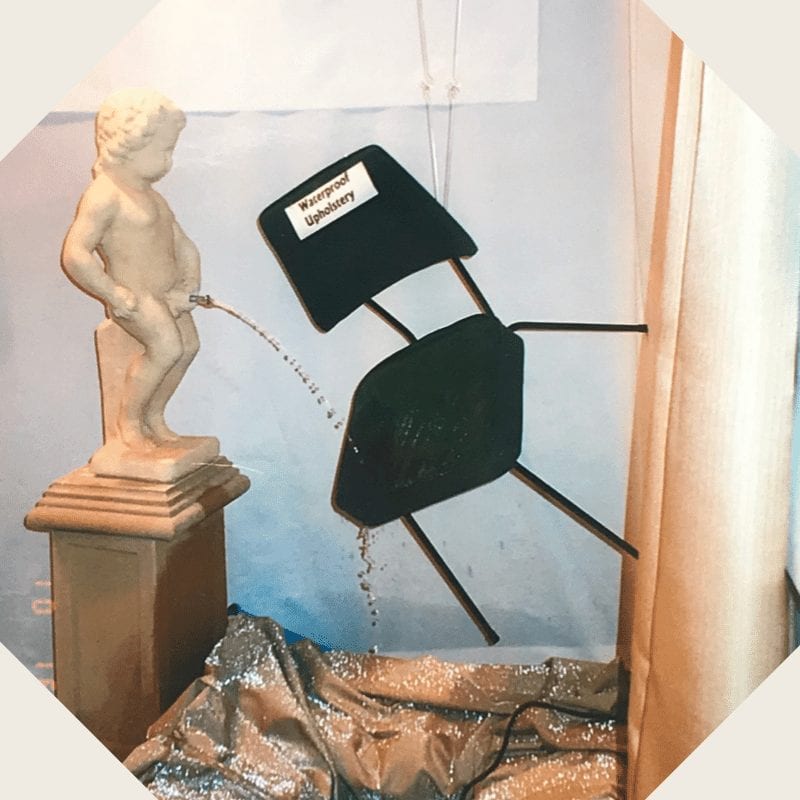

1993 – Introduction of Crypton

Craig and Randy Rubin hatched an ingenious plan from the basement of their Michigan home. The super duo wanted a fabric that could stand up to life’s messes and still be touchable and beautiful, a fabric that would change the way many people live their lives. Crypton was born and has become an essential part of the contract furnishing industry.

Materialised brought this revolution to Australasia. In fact Materialised was Craig and Randy’s first export client. The rest is history.

1995 – Fabrics For The Real World

In 1995 our first Fabrics For The Real World training program was created to share our experience in developing and delivering performance Fabric to the contract market, with Designers and Specifiers.

By presenting this compact program to Students and Design practitioners we give back to the industry that has been very kind to us, which in turn delivers better outcomes for those occupying the spaces we furnish.

1999 – Our First Digital Printer

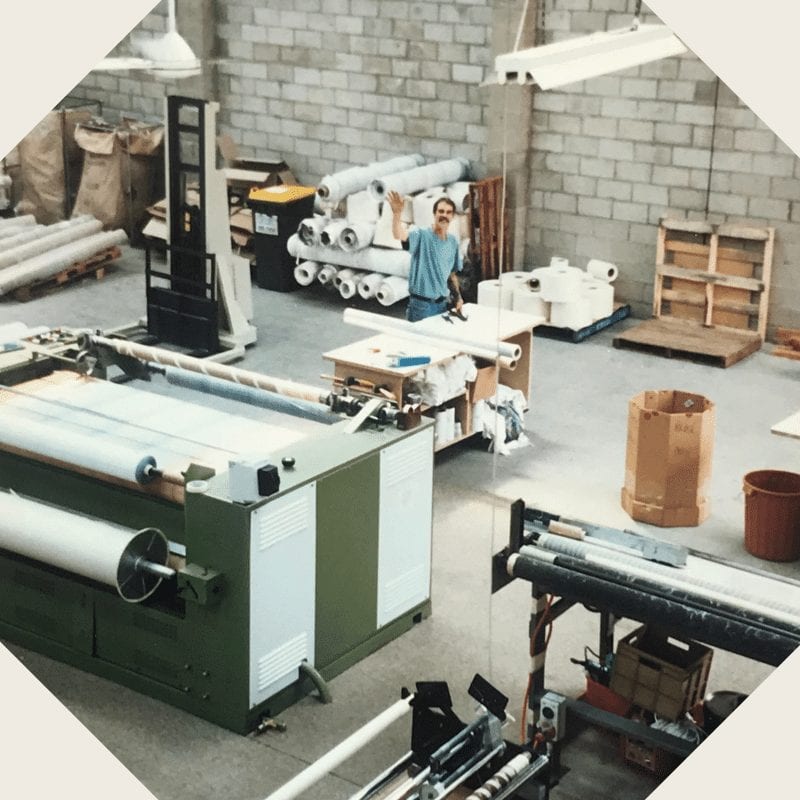

Dye Sublimation Printing (AKA Transfer Printing) – In the early days the transfer paper was produced mostly off shore by Rotogravure method. As the name suggests it involved engraving rollers to create designs.

These transfer papers were applied to a variety of base fabrics by means of pressing them together with the fabric at high temperature and pressure where the design actually integrates with the polyester molecules.

We initially outsourced our transfer process and eventually purchased our own Lemair equipment in 1993.

Just before Sydney hosted the Olympic Games our very first, very slow, digital printer was installed.

Happy days! We were no longer at the mercy of outsiders.

From those early days where we marvelled at the 4 square metres an hour production, to where now we print at 200 times that snails pace, and we marvel even more!