Reflecting on 40 years of Materialised evokes wonderful memories of the amazing people who have been part of our furnishing textiles journey. And there have been many.

Probably even more interesting to my readers are the massive changes the furnishing textile supply industry has undergone, and the part we have had the privilege to have played.

Furnishing textiles in the 1980’s

Materialised was born in an era when it was possible to create a viable range of textiles in our own country.

The accepted model was textile manufacturers produced ranges of designs, usually by their in-house designers. These ‘collections’ were presented to wholesalers who made their own choices as to what was presented to retail drapery stores or furniture manufacturers, and in turn consumers purchased their choice.

Every step of the process involved the opinions and speculation of many. This resulted in overly-edited and sanitised products, design and colour being available.

– Gary Price

Another form of filtering the choices of what was available was a confusing tariff and licensing regime. 40% duty and license fees of $1 per square metre were punitive and distorted choice.

We decided to be different!

Not just for the sake of being different but to actually make a difference. We decided to focus entirely on Australian and New Zealand production. Not just furnishing textiles but the printing and fabrication of homewares.

Little by little our ambitions were eroded. Within our first decade the Australian textile industry was in free-fall. Week by week, yarn spinners, weaving mills, dye houses and those supporting industries were closing, due to dropping tariffs in the pursuit of what was described by our Government as having a ‘level playing field’. Sadly, Australia was the only country playing on the field.

So, we changed course. Given we could not depend entirely on local production we vigorously pursued at least adding value locally.

Dye sublimation of polyester textiles was in its infancy

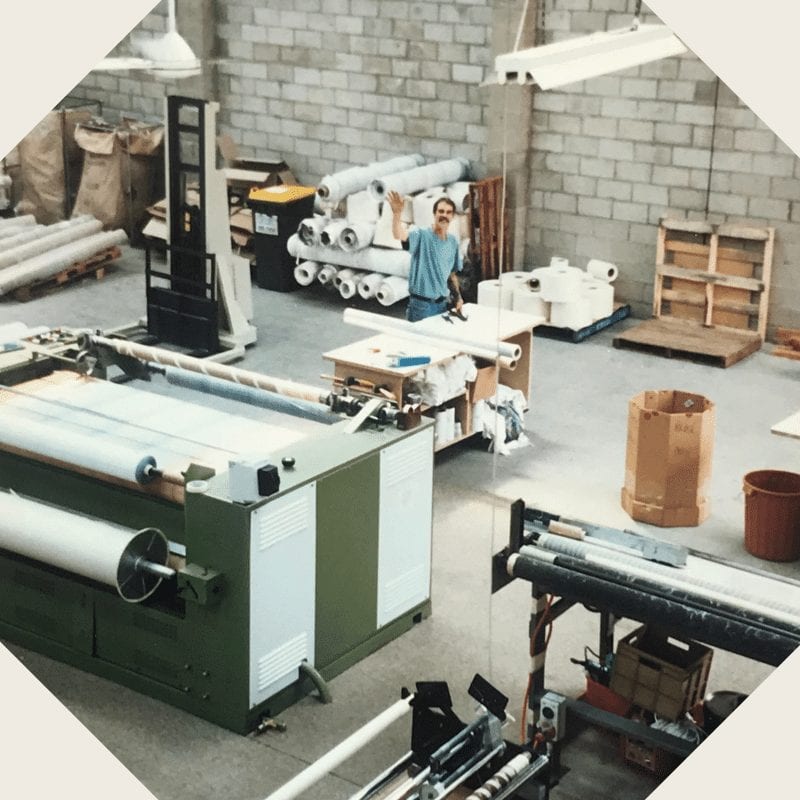

The process involved printing dye onto a release paper and activating the dye by pressing at high temperature the subject fabric and paper through pressure rollers known as a Calendar (our first calendar printer, pictured below). The revolution began!

The choices of design and base cloth was getting closer to being in the control of Interior Designers and their clients. Opening up choices like never before.

In the mid 1980’s Flame Retardancy became a major focus, especially in textiles for institutional uses. The means of achieving Flame Retardant textiles was to either apply a topical finish to or, as we decided, to weave using inherently F/R polyester yarns, predominantly Trevira CS (comfort & safety)

Another revolution began…

Dye sublimation (transfer printing) polyester was a perfect solution to adding pattern and colour to these new Flame Retardant fabrics. Perfect marriage!

By the mid 1990’s aged care facilities were making great strides in improving their interiors. Nursing homes wanted to be more ‘residential’ and replace the institutional looking vinyl upholstered furniture with textile was key to achieving that outcome.

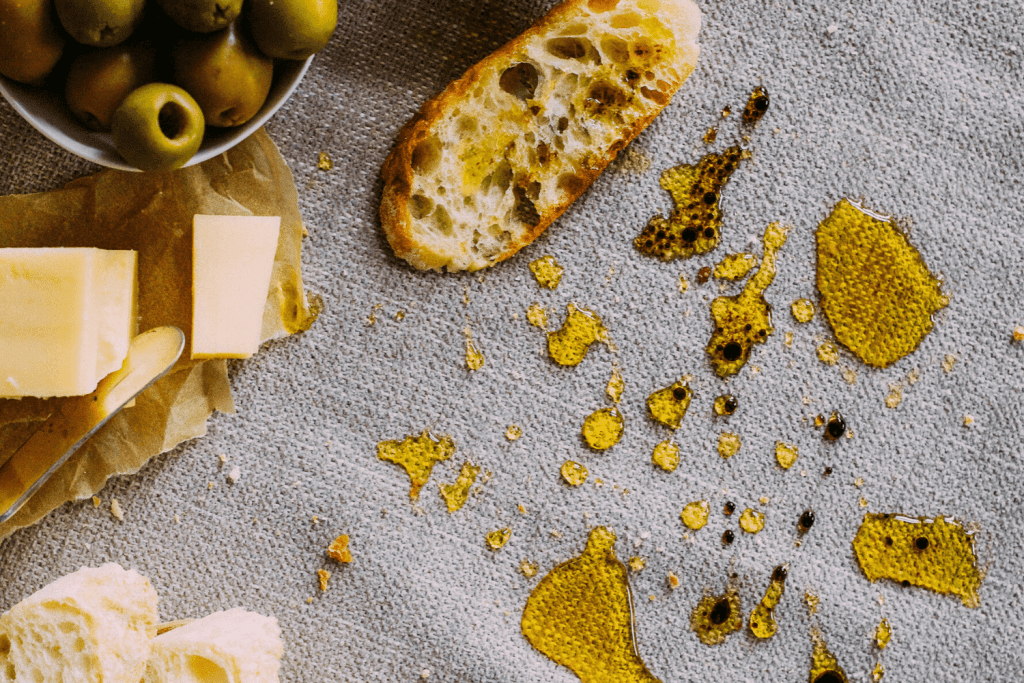

Enter Crypton waterproof fabrics!

Crypton was a very innovative solution to give waterproof and soil release features to upholstery fabrics whilst retaining the breathability and comfort of a textile upholstery. Proudly, Materialised introduced this new game-changing product to Australia and New Zealand. Healthcare and hospitality facility furniture has changed dramatically for the better.

Midway through our history, the digital revolution entered

Where previously transfer paper was printed by traditional Roto-Gravure method which, as the name suggests involves engraved rollers. Production runs were large and, as mentioned earlier, this necessitated speculation seriously restricting changes in design and colour.

Digital printing in wide format held the advantage of eliminating the speculation and the associated waste and even better, the restriction of pattern-repeat associated with roller printing was eliminated. Our first serious order was an Olympic Games banner with a 70 metre (yes 70) repeat!

The genie was out of the bottle and there was no holding him back.

From that first printer with an output of about 2 metres an hour, our capability is now more like 600 metres per hour and includes 3 metre width capability.

– Gary Price

Julian Treasure, a British Acoustic and communication consultant unkindly asked the question, “Don’t Architects have ears?” As Acoustics became a much greater focus in design, Materialised moved rapidly to introduce a number of solutions.

Acoustics

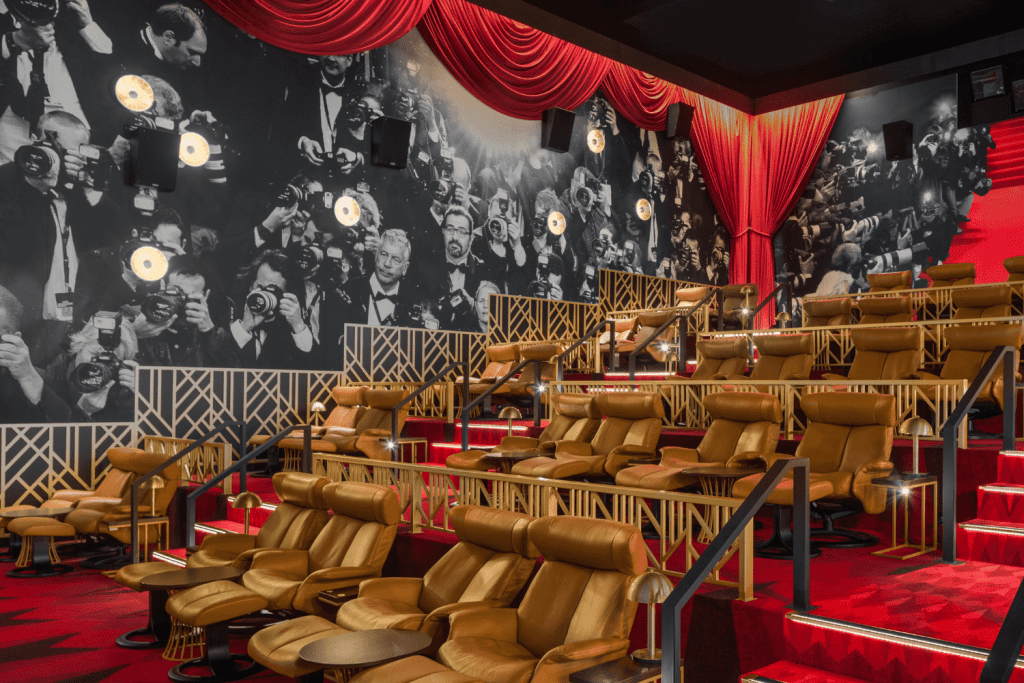

Firstly, WhisperWall, a sophisticated system to upholster walls addressing acoustic and imagery, moved us into the acoustic solutions arena with a vengeance. WhisperArt closely followed offering the dual advantage of taming a space acoustically and serving as occasional art pieces.

Our next move was to develop an acoustic sheer. Based on a novel principle developed by Professor Maa, known as ‘Perforated Foil Principle,’ our Hush Sheers translate the principle into a woven semi-sheer curtaining textile, by intricately weaving special yarns to achieve a very satisfactory 0.6 NRC.

Then there was WeaveUp!

This web-based platform heralds a radical change in the way textiles are, and will continue to be delivered. To explain the name, WeaveUp is the antipathy of the textile world’s expression ‘down weave’, used where one wants to reduce cost and sacrifice quality. Contrarily, WeaveUp adds value!

Holding in excess of 40,000 designs from around the globe, suitable prints can easily be selected and even manipulated through colour, scale and repeat. Then comes the base cloth choice, from filmy sheers to robust upholsteries. Once selected, print samples are ordered online and dispatched within 48 hours.

There are enormous implications to this technology! It places control of every aspect of the interior design process where it should be; in the hands of the Interior Designer. It’s ecologically sustainable with no waste through physical speculation on fabric or samples. It is printed in Australia, rapidly! Royalties are remitted to the textile designer on all sales. Everyone wins with WeaveUp!

Our designer collaborations

I cannot conclude without mentioning the pride we feel in having so many talented designers entrust us with handling their art. At the time of writing we represent Florence Broadhurst, Jimmy Pike, Sibella Court, Grace Garrett, Patricia Braune, P/Kaufmann, Lynne Tanner, Sara Berrenson, Typoflora and Metsovaara.

40 years of Materialised

It has been a wonderful journey, and in many cases, we have had the privilege to be at the forefront of change in our industry.

We may not be the biggest player in the industry, but we did set out to leave a legacy, not a dynasty.

The Prices.