How durable and lightfast is our commercial-grade printed fabric exactly? Many of you will be familiar with the rub rate of our woven fabrics and base cloths. But what happens to these results when the fabric is printed with a design?

This is a very good question!

We chose two printed fabrics and put them to the test in our in-house lab. Curves Rust Teal by Patricia Braune and Mineral Sapphire by Shibori were both printed on our base cloth Peau De Peche.

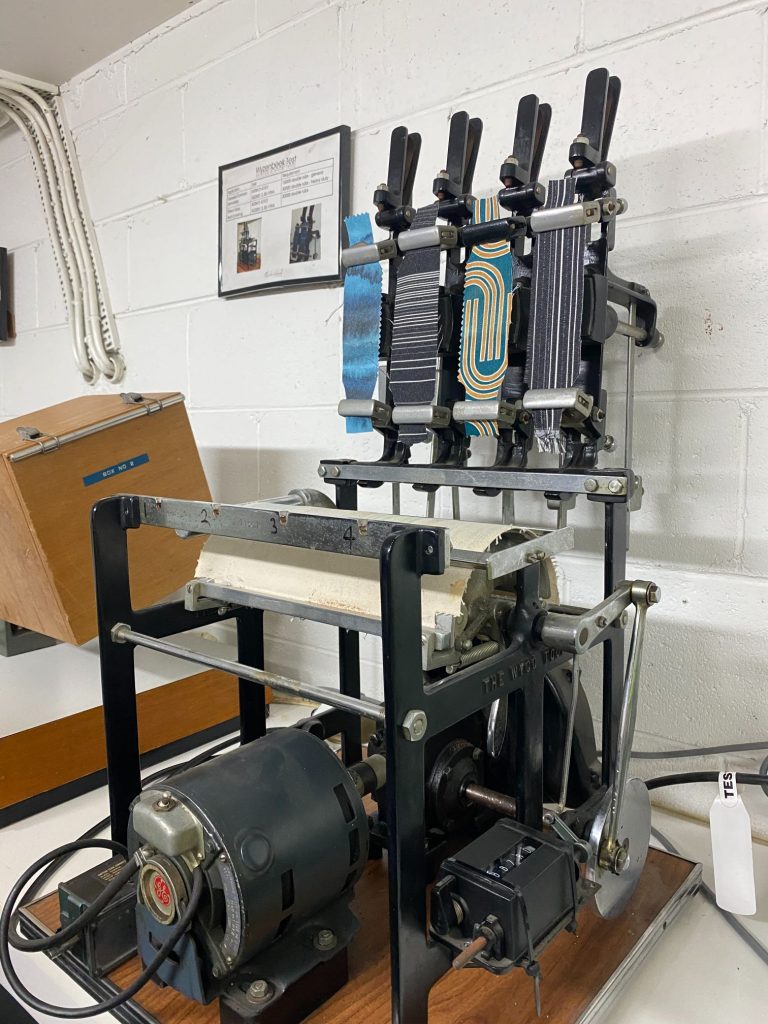

The Wyzenbeek Test – Durability

Wyzenbeek testing plays a crucial role in assessing the durability and performance of textiles, particularly when it comes to commercial-grade fabrics. It is a widely accepted method used to determine a fabric’s ability to withstand abrasion and evaluate its resistance to wear and tear. The testing process involves a machine that rubs a piece of fabric against a standard abradant in a back-and-forth motion, simulating the friction that occurs during normal use.

The importance of Wyzenbeek testing lies in its ability to provide objective and quantitative data about a fabric’s durability. By subjecting fabrics to controlled abrasion, it helps manufacturers, designers, and buyers make informed decisions about material selection for applications where frequent use and high traffic are expected, such as in contract furnishings, upholstery, and automotive interiors.

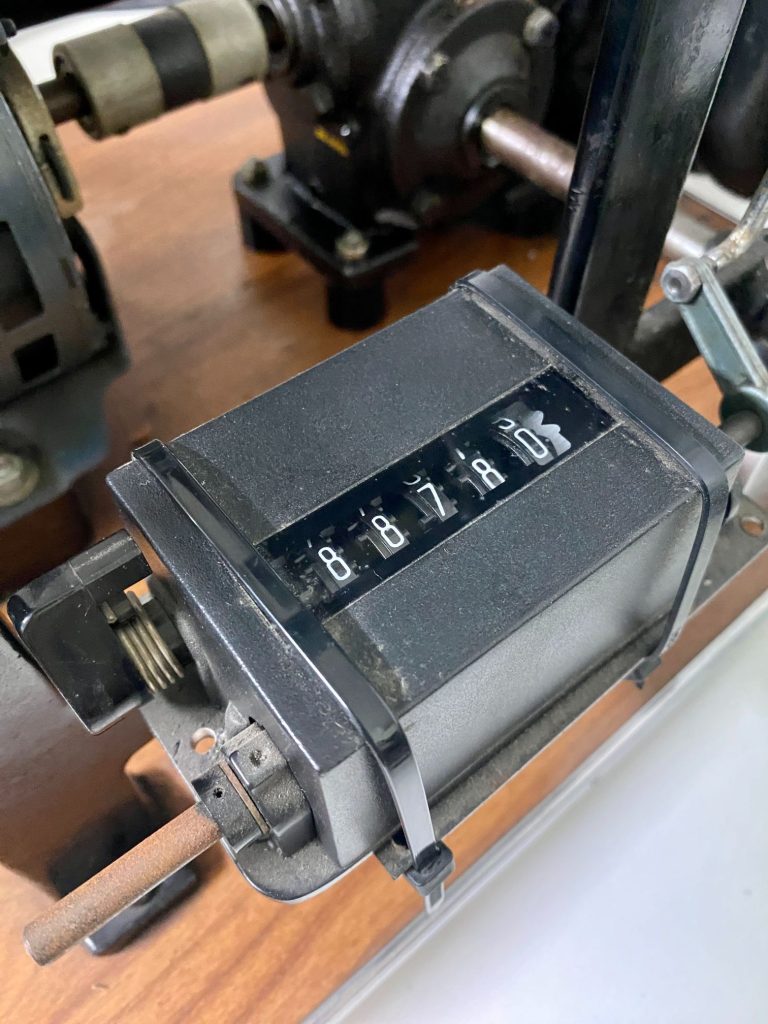

The results obtained from Wyzenbeek testing are expressed as double rubs, which represent the number of times the fabric can withstand abrasion before showing signs of wear or damage. These results serve as a standard measure for comparing the durability of different textiles.

Commercial-grade fabrics usually have higher double rub ratings, indicating superior strength and longevity. While there is no universal standard for commercial-grade fabrics, a widely accepted benchmark is a minimum of 30,000 to 40,000 double rubs for moderate commercial use and 100,000 double rubs or more for heavy-duty commercial use.

Wyzenbeek Test Results – Commercial-Grade Printed Fabric

Our two printed fabrics easily tested to 75,000 double rubs with no sign of wear. They only started to show slight signs of deterioration at about 82,000 double rubs and did not reach their end point.

This is an exceptional result and clearly proves that with our dye sublimation printing method at very high heat, we’re dying the raw element of the fibre so that it’s integrated into the fabric, not onto the fabric.

Blue Wool Test – Lightfastness

The Blue Wool Test is a widely recognised method used to evaluate the colourfastness and lightfastness of textiles, particularly commercial-grade fabric. It involves exposing fabric samples to standardised conditions of light and moisture, simulating real-life usage, and assessing the resulting colour changes.

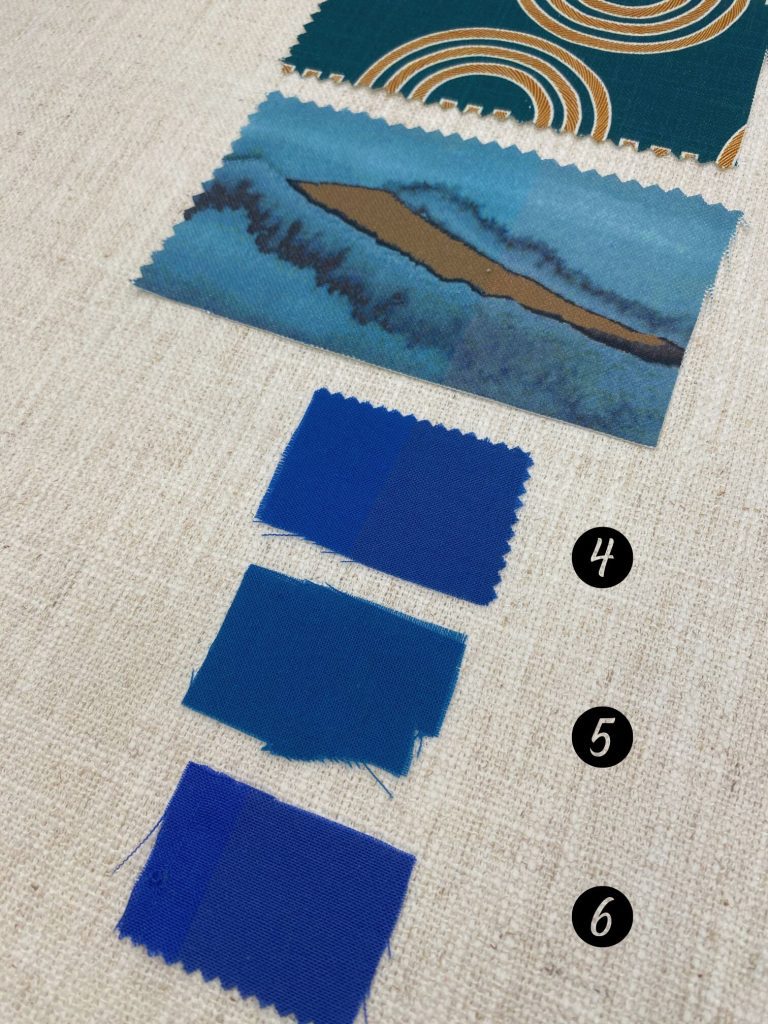

The test is named after the Blue Wool Standard, which consists of a series of eight blue wool fabric samples with varying degrees of lightfastness.

During the test, commercial-grade printed fabric samples are subjected to artificial light sources that emit both ultraviolet (UV) and visible light. The samples are exposed for a predetermined period, which can vary depending on the specific standards being followed. Additionally, the samples are typically subjected to moisture or humidity to simulate real-life conditions.

The test results are then compared to the Blue Wool Standards, which serve as a reference for evaluating the fabric’s performance. Each standard represents a specific level of lightfastness, ranging from 1 (very poor) to 8 (excellent). By comparing the colour changes in the fabric samples to the colour changes in the standards, it is possible to determine the fabric’s lightfastness rating.

For commercial-grade fabrics, it is generally expected that they meet a minimum requirement of a specific lightfastness rating. This requirement varies depending on the intended use of the fabric and the industry standards governing it. Higher-grade fabrics intended for outdoor applications or areas exposed to significant sunlight may require a higher lightfastness rating to ensure durability and long-lasting colour retention.

Blue Wool Test Results – Commercial-Grade Printed Fabric

After 98 hours of testing, our commercial-grade printed fabric scored 7 in the Blue Wool Test. Another exceptional result!

In summary, using Wyzenbeek testing, and the Blue Wool Test are valuable tools for assessing the durability, colourfastness, and lightfastness of commercial-grade printed fabric. See our Wyzenbeek machine in action.

They allow for the objective assessment of the fabric and provide valuable information for material selection in various applications. By understanding the standard accepted results, manufacturers and consumers can make informed choices based on the expected level of wear and tear our printed commercial-grade fabric can endure, ensuring long-lasting and high-performing products.

Note – each print design and textile base substrate would achieve a different result. By selecting rich colours on our Peau De Peche base cloth for this test, you get a sound idea of the high-performance of our printing process results.